The value of this achievement can be understood from three dimensions: technological breakthrough, industrial application, and corporate strategy:

Dimension | Core Significance | Detailed Explanation |

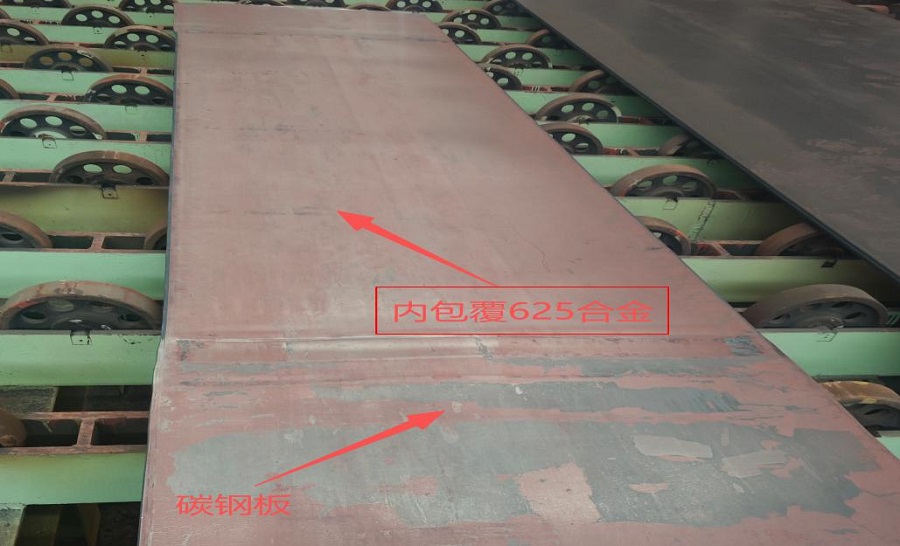

Technological Breakthrough | Overcame the challenge of producing "thin and wide" high-end alloys | Addressed the rolling bottleneck for high-difficulty special materials such as Inconel 625 alloy plate (high-strength, high-corrosion resistance) – transitioning from "medium-thick plates" to "1mm-class ultra-thin wide plates". The core lies in the innovative "vacuum roll bonding diffusion composite" process, which bonds multi-layer slabs through roll bonding, breaking traditional rolling limits and enabling flexible production of various specifications. |

Industrial Application | Broke monopolies and realized independent control of key materials | This technology allows stable domestic production of high-quality, wide-width special alloy thin plates, breaking foreign technological barriers. The products can be used in high-end fields such as aero-engines, petroleum refining, and nuclear power, providing critical material support for the industrial chain. |

Corporate Strategy | Consolidated technological barriers and seized market high ground | As the first domestic manufacturer to master this technology, Gallianz's success is an extension of core patented technologies. It not only demonstrates the capability to meet customized needs of high-end customers but also provides solid competitiveness for the company to expand into international markets (Indonesia, Middle East). |

This breakthrough not only solves a key process challenge in material processing but, more importantly, advances China's "raw material independence" for critical equipment in aerospace, energy, and other sectors. It reduces reliance on imported special materials in key fields and represents the company's leap from "being able to produce" to "leading innovation".