253MA (UNS S30815) is a heat-resistant austenitic stainless steel micro-alloyed through the addition of nitrogen and rare earth elements. It achieves an excellent balance among high-temperature strength, oxidation resistance, and cost efficiency.

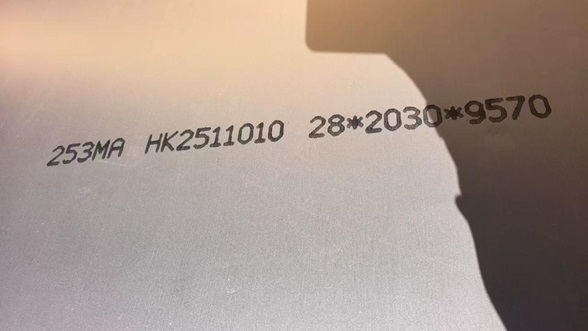

Gallianz's Medium Plate Rolling Mill

| Property Category | Main Advantages |

|---|---|

| High-Temperature Strength | Exhibits high creep strength and rupture strength in the temperature range of 850 °C–1100 °C. Its high-temperature strength is superior to that of 310 and 309 stainless steels. |

| Oxidation Resistance | With the addition of cerium (Ce) and silicon (Si), it provides excellent oxidation resistance, maintaining outstanding performance in air at temperatures up to 1150 °C. |

| Corrosion Resistance | High chromium and nitrogen contents give it pitting corrosion resistance close to that of 316 stainless steel, along with good high-temperature corrosion resistance in oxidizing atmospheres containing carbon, nitrogen, and sulfur. |

| Structural Stability | The austenitic structure ensures good toughness, including low-temperature toughness, and offers excellent resistance to sigma (σ) phase precipitation. |

| Fabrication Properties | Good formability and weldability; suitable for all standard fusion welding processes. |

| Cost Effectiveness | Compared with high-nickel alloys and 310 stainless steel, its lower nickel content combined with superior performance provides a more economical solution. |

The performance of 253MA is fundamentally based on its chemical composition:

Chromium (Cr): 20.0–22.0% — provides essential oxidation and corrosion resistance

Nickel (Ni): 10.0–12.0% — stabilizes the austenitic structure

Nitrogen (N): 0.14–0.20% — significantly enhances high-temperature strength and creep resistance

Silicon (Si): 1.40–2.00% — improves oxidation resistance

Cerium (Ce): 0.03–0.08% — a rare earth element that markedly improves oxide scale adhesion and high-temperature performance

Tensile Strength: ≥ 600 MPa

Yield Strength: ≥ 310 MPa

Elongation: ≥ 40%

Hardness: Max. HRB 95

Gallianz's 253MA (S30815) Quality

Outstanding Heat Resistance: Heat resistance is the core advantage of 253MA.

Oxidation Resistance: At continuous service temperatures up to 1150 °C, it forms a thin, dense oxide layer that remains stable even under thermal cycling conditions.

Creep Resistance: The addition of nitrogen and rare earth elements provides creep resistance at high temperatures comparable to certain nickel-based alloys.

Performance in Complex Atmospheres: Performs well in sulfur-containing oxidizing atmospheres. However, in strongly carburizing and reducing atmospheres, alloys with higher nickel content may be a better choice.

Good Corrosion Resistance: Although not specifically designed for liquid corrosion environments, its corrosion resistance remains notable.

Pitting corrosion resistance is comparable to that of 316 stainless steel.

It should be noted that due to its relatively higher carbon content, there is a tendency for sensitization after welding or exposure to certain temperature ranges (425–860 °C), which may reduce resistance to intergranular corrosion.

Welding: 253MA exhibits good weldability. Matching consumables are recommended (e.g., 22.12HT electrodes). Preheating is not required, but low interpass temperatures should be maintained and overheating avoided.

Heat Treatment: Standard solution annealing at 1050–1150 °C followed by rapid cooling (air cooling or water quenching).

Forming and Machining: Cold forming should be carried out at room temperature. Hot forming requires uniform heating to approximately 1100 °C, with the final forming temperature not lower than 900 °C. During machining, sharp tools and appropriate cutting parameters are essential.

253MA is a cost-effective heat-resistant steel that delivers outstanding performance in the temperature range of 850 °C to 1100 °C. Through an innovative micro-alloying design, it achieves high-temperature performance close to that of high-alloy materials at a relatively lower cost, making it an ideal substitute for more expensive 310 stainless steel or certain nickel-based alloys in demanding thermal environments.

Typical applications include:

Industrial Furnace Equipment: Furnace rollers, radiant tubes, burner components, conveyor belts, etc.

Energy and Environmental Protection: Central tubes of cyclone separators in circulating fluidized bed (CFB) boilers.

Petrochemical and Chemical Industries: Ethylene cracking furnace tubes.

Metallurgy and Building Materials: Sintering equipment and cement production equipment.