For Original Equipment Manufacturers or end-users, wear and weight represent real issues for handling, extraction, crushing and sorting machinery. For all that equipment, service life, performance of use and energy efficiency are closely linked to the perfect suitability of steels. Gallianz offers the widest range of thicknesses and the proven best materials of clad plates adapted to each specification.

Metal clad wear-resistant materials are with high wear resistance and good impact performance. They can be cut, bent, welded, etc. They are able to be bolt connection with other structure. In the process of the maintenance, they are time-saving and convenient. Therefore, for equipment users, to choose qualified machinery with excellent performance is quite important. Gallianz can provide nickel and nickel-base alloy-clad steel plates, titanium steel clad plates, titanium stainless steel clad plates, copper steel clad plates, aluminum steel clad plates, etc. for your special equipment.

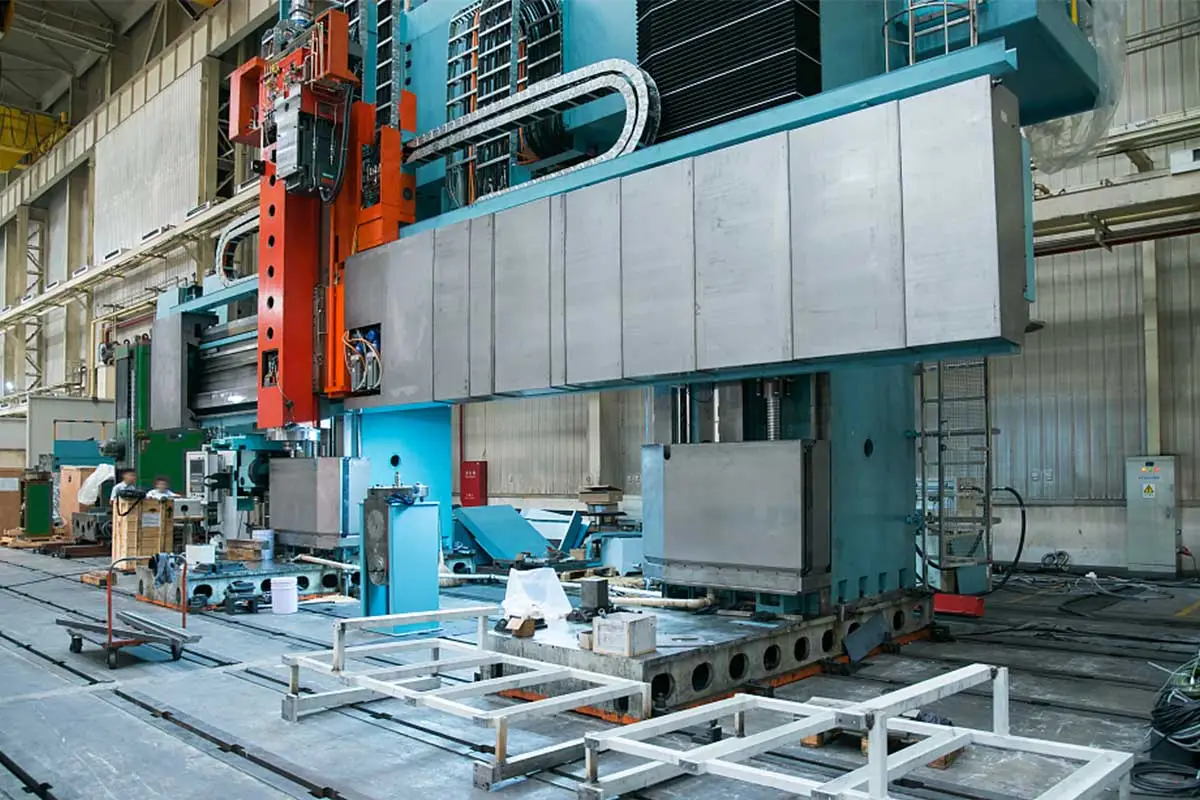

Metal clad plates have extensive applications in the machinery industry due to their unique characteristics and performance advantages.

One key application of metal clad plates is in the manufacturing of machinery components that require a combination of different properties. By combining different materials, metal clad plates can provide excellent strength, corrosion resistance, wear resistance, or heat resistance, depending on the specific requirements of the machinery.

Metal clad plates are used in the fabrication of gears, bearings, shafts, and other high-stress components. The clad material provides enhanced durability and reliability, while the base metal provides the necessary structural strength.

Additionally, metal clad plates find application in the construction of machinery parts exposed to aggressive environments or corrosive chemicals. The clad layer acts as a barrier, protecting against corrosion and extending the lifespan of the components.

Moreover, metal clad plates offer design versatility, allowing for the customization of machinery parts to meet specific requirements. The ability to combine different metals or alloys provides flexibility in terms of material selection and performance characteristics.

Overall, metal clad plates have become indispensable in the machinery industry, providing enhanced performance, durability, and corrosion resistance in critical components. Their usage contributes to the efficiency, reliability, and longevity of machinery and equipment.