It is also very practical technical service for the clad plate. The entire manufacturing process has been automated in Gallianz for the bevelling of the clad plate's edges. When the plate edges are bevelled, the roughness degree of the clad plate edges are greatly improved, and the required welding slops can be showed out. which is relatively easy to meet the conditions required for welding. Bevelling edges are better than cutting edges. Bevelling edges are with less welding defects and a high welding pass rate. If the clad plate is too poor, it is easy to produce an off-bevelling and knife-stopped phenomenon, and we need to pay an attention to the phenomenon of plate correction.

In order to ensure the quality of welding, it is necessary to prepare the workpiece before welding by cutting it into a groove shape. To ensure a strong weld joint, a chamfer is milled at the edge of the plate, creating a slope opening.

The purpose of the groove surface is as follows:

It allows the welding rod or torch to reach the bottom of the piece directly.

It facilitates the removal of slag during the welding process.

It enables the welding rod or torch to move in the groove, ensuring good fusion.

The choice of welding joint form and groove shape depends on the requirements of material thickness and welding quality. Common groove forms include K, V, I, U, X, and the V shape is widely used.

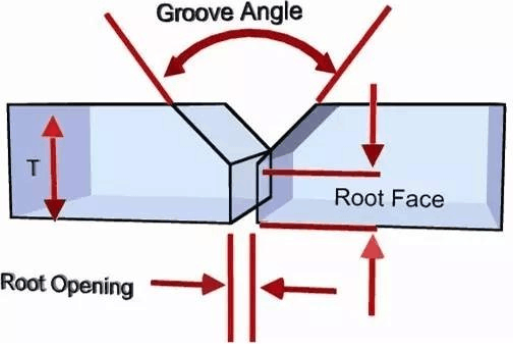

V shape:

The groove surface is the area where welding takes place.

Two groove surfaces create an angle that helps with the filler material during welding.

The gap left between the joint roots before welding is referred to as the root gap. Its purpose is to ensure proper root welding penetration. The root gap is also known as the assembly gap.

The straight edge at the end of the joint's root is called the root face. This straight edge helps prevent burn-through of the root during welding.

By modifying the wording, the meaning remains the same while reducing repetition.

PHONE

ADDRESS

No.20 Yongtai Road, Pingqiao High-tech Industrial Park, Yu 'an District, Lu' an City, Anhui Province, P.R.China.